The production dynamics in watchmaking, both in Japan and elsewhere, are highly complex and have been a topic of considerable debate, particularly since it became common practice for companies to shift part of their manufacturing to countries with lower costs.

In this article, I’ll delve into where and how Seiko Group watches are produced, and I’ll explain the differences between “Made in Japan” models and those that aren’t.

What does “Made in” really mean?

When we buy a watch marked “Made in Japan” or “Swiss Made”, it’s easy to assume that every component was designed, manufactured, and assembled entirely in the country listed on the label.

This assumption becomes even stronger when the association of a product with a certain country is one of its main selling points, highlighted by advertising campaigns and marketing aimed at consumers.

In reality, to use the Swiss Made label, companies need to ensure that at least 60% of their production costs are incurred in Switzerland. Until 2017, regulations required an even lower percentage. This means that a watch promoted as “Swiss Made” can indeed include components produced in, for example, China or other countries with lower costs.

“Made in Japan” is governed by different regulations, which do not specify a precise percentage of production costs but establish that the “country of origin” is considered to be the country where a procedure resulting in a “substantial transformation” of the product’s content was performed.

In simpler terms, if a watch undergoes a “substantial transformation” in Japan, companies are permitted to use the “Made in Japan” label, even if some parts are made in other countries.

Moreover, it’s not clearly defined what constitutes a “substantial transformation”, leaving room for various interpretations.

For these reasons, you may encounter “Made in Japan” watches that incorporate parts produced in other countries. For example, numerous entry-level or mid-range models feature cases manufactured in facilities located in China.

If you want to explore the Japanese regulations in more detail, here are some references (in Japanese):

- Act for the Prevention of Unfair Promotional Practices and Misleading Advertising

- Misleading statements regarding a product’s country of origin

Where are Seiko watches produced?

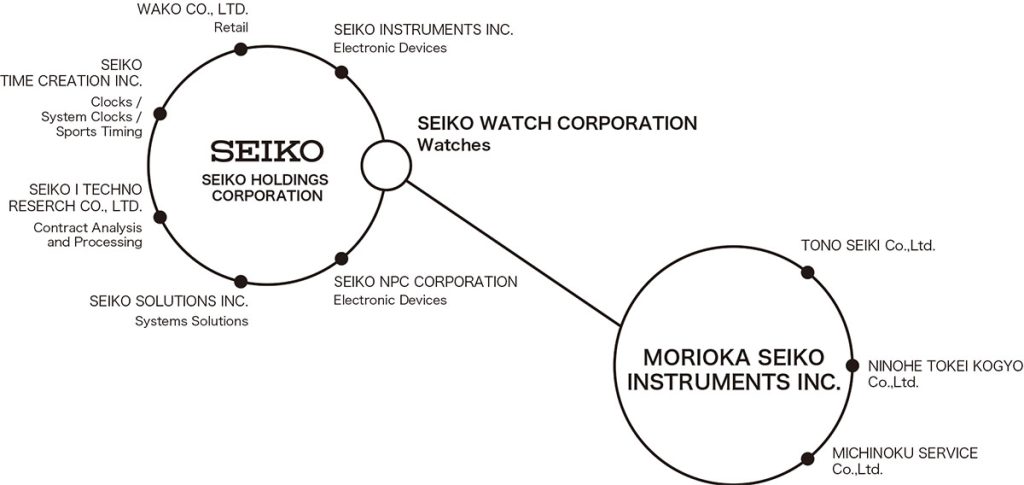

When talking about Seiko, we’re actually referring to a group of companies whose activities span numerous sectors. Watch production, which is only a part of these companies’ activities, is primarily entrusted to two partially independent groups that evolved from Daini and Suwa Seikosha, two names that will be familiar to enthusiasts of the Japanese brand’s history.

Seiko Instruments Inc. (formerly Daini Seikosha), headquartered in Chiba, is a subsidiary of the Seiko Group Corporation. It manages many subsidiary companies, both in Japan and abroad.

Seiko Epson Corporation (formerly Suwa Seikosha), headquartered in Suwa in Nagano Prefecture, is a publicly listed company. It controls numerous subsidiaries, including Orient.

Seiko Instruments and Seiko Epson manage various facilities, both in Japan and worldwide, and they can produce virtually every component needed to manufacture their watches in-house.

These parts, which in some cases may come from facilities in different countries, are later assembled to create the final product.

This in-house vertical integration, along with direct control of the group’s factories, ensures uniform quality standards.

Seiko facilities in Japan

The main Japanese factories for the Seiko Group’s watch production are in the Iwate and Nagano Prefectures.

In Iwate, there are the Morioka Seiko Instruments facilities, a subsidiary of Seiko Instruments Inc., where, among other things, many mechanical models are produced. Meanwhile, in Nagano, you’ll find Seiko Epson’s factories, which mainly produce quartz and Spring Drive watches.

Following the integration of the Orient group, Seiko Epson further expanded its production network and today also controls the facilities in Yuzawa, Akita Prefecture.

Morioka Seiko Instruments and the Shizukuishi Watch Studio

Iwate Prefecture, located in the Tōhoku region in northeastern Japan, is renowned for its vast mountainous landscapes and its spectacular rugged coastline along the Pacific Ocean. Dominated by the Ōu Mountain Range, which runs from north to south, and by the imposing Mount Iwate, the region offers breathtaking natural scenery.

The Morioka Seiko Instruments facilities produce a significant number of watches and movements for various group brands, spanning a wide range of price segments.

In 2020, the new Grand Seiko Studio Shizukuishi was inaugurated, where the Grand Seiko 9S family watches are made, as well as other high-end timepieces.

From the official Grand Seiko website: “In this studio, every aspect of watch manufacturing, from design through the making of movement components to the assembly, adjustment and inspection of complete watches is carried out by Grand Seiko’s own craftsmen and women”.

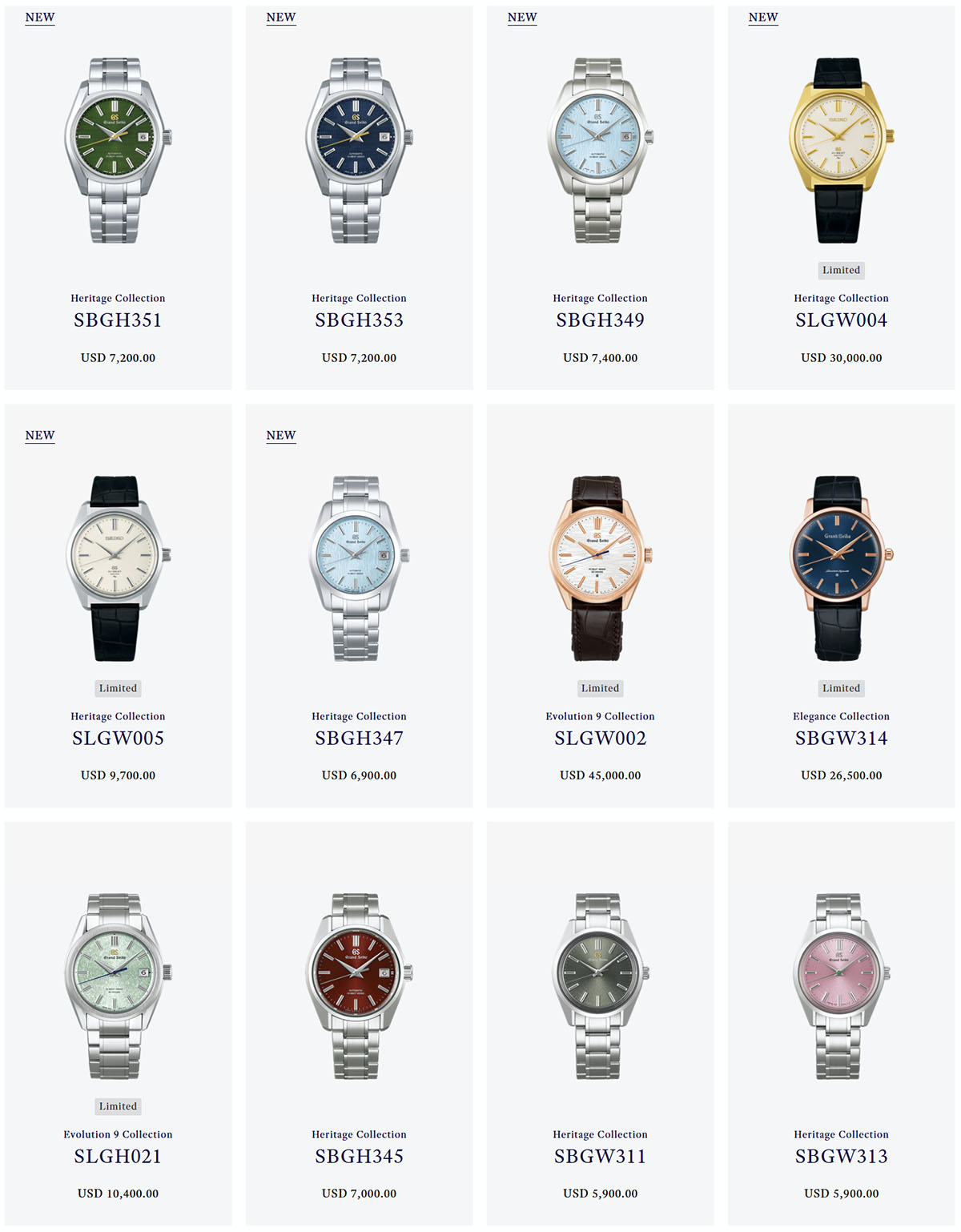

Among the pieces made in Shizukuishi are true masterpieces of haute horlogerie, highlighting the artisans’ skill at the Grand Seiko Studio.

Examples include the Grand Seiko Kodo Constant-force Tourbillon, featuring the 9ST1 caliber, and the Credor Fugaku Tourbillon, with the 6830 caliber.

A very important part of production at the Grand Seiko Studio Shizukuishi is the extensive range of models with mechanical 9S family movements, such as the following examples.

Moving on to Seiko-branded watches but remaining in the high-end segment, we find models equipped with 8L family movements, such as some of the brand’s most prestigious dive watches.

Notable examples include references SBEX011/SLA039, SBEX009/SLA037, and SBDX035/SLA041, which house the automatic calibers 8L55 and 8L35, produced at Shizukuishi.

The finishing on the cases is also worth mentioning, featuring superb contrasts between brushed and polished surfaces achieved through Zaratsu polishing.

Regarding Zaratsu polishing in general, it’s worth noting that this finishing must be done by hand, and Seiko currently performs it only in Japan. This means that all cases featuring Zaratsu polishing were hand-finished in Japan.

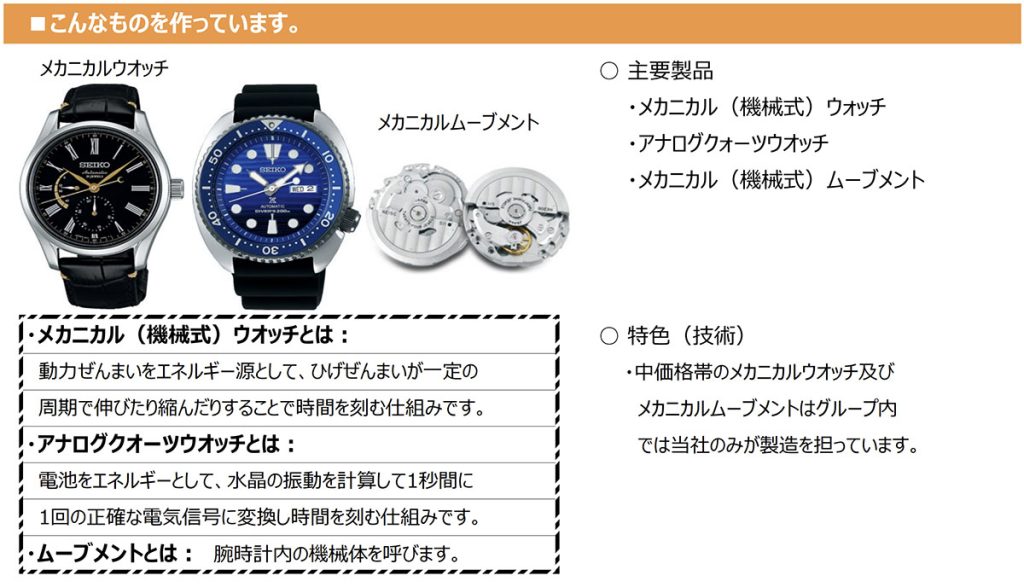

The Ninohe Tokei Kogyo plant, located slightly further north from Shizukuishi in Iwate Prefecture, produces many of the mid-range and entry-level “Made in Japan” mechanical watches.

In a January 2024 report on Iwate Prefecture’s official website, the main activities carried out at the Ninohe plant are described.

The production is described as follows (translated from Japanese): “With our state-of-the-art automated assembly line and the expertise of highly skilled artisans, we manufacture mechanical and analog quartz watches, as well as their movements. Within the group, we stand out as a specialized production hub for entry-level to mid-range Japan Made watches, offering our products to the global market”.

The original text (in Japanese): “自動化を追及した最先端の自動組立ラインと、熟練技術者による高度な組立技術で、機械式及びアナログクォーツ式ウオッチ完成品と、そのムーブメント(機械体)の製造を行っており、グループの中でも、普及価格帯から中級価格帯のウオッチ生産拠点として、Japan Madeの製品を世界に提供しています。”

It explains that production consists of entry-level mechanical watches, analog quartz watches, and watch movements.

In an image showing some of the products made there, we see a Seiko SARW013 with automatic caliber 6R27 (list price 143,000 yen) and a Turtle “Save The Ocean” SBDY021 with automatic caliber 4R36 (list price 61,560 yen).

Next to the watches, there are also two automatic movements pictured, calibers NE15C and NE20B, both intended for sale to third parties for watches not carrying the Seiko brand.

On another Japanese website about the Ninohe plant, additional details about the company are given.

Ninohe Tokei Kogyo Co., Ltd. was established in 1974 as a factory exclusively dedicated to producing components for Morioka Seiko Instruments Inc. It shares the same corporate philosophy, “Sincerity, Trust, and Gratitude”, as its parent company, Seiko Instruments Inc.

Currently, the company conducts two main operations: final watch assembly (casing) and movement production. With pride and dedication to Japan Made products born in Ninohe, the company strives to deliver trust and reliability in the work of all its employees. This spirit, unchanged for 40 years, will continue to guide the company in the future.

The explanation goes on to say that entry-level models are produced on automated assembly lines, while mid-range models are assembled by hand by skilled technicians to meet strong demand both in Japan and overseas.

In addition to assembly (casing), which involves both automation and craftsmanship, we also undertake movement assembly and component processing.

Our corporate goal is for the mid-range and entry-level SEIKO watches labeled “Japan Made”, manufactured by Ninohe Tokei Kogyo, to be widely recognized and appreciated by customers worldwide. Achieving this goal will not only be a source of pride for our employees and the Ninohe community, but will also contribute to our company’s growth and the region’s economic development.

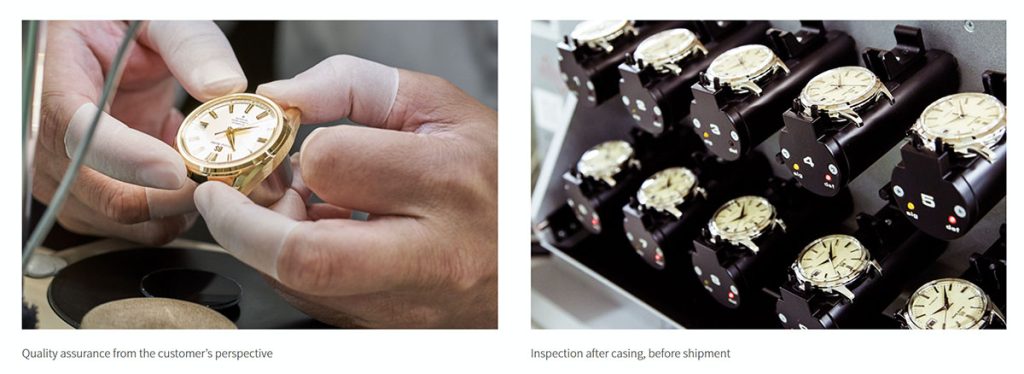

From the various sources I’ve consulted, it’s clear that production processes differ among watches and movements in different price tiers.

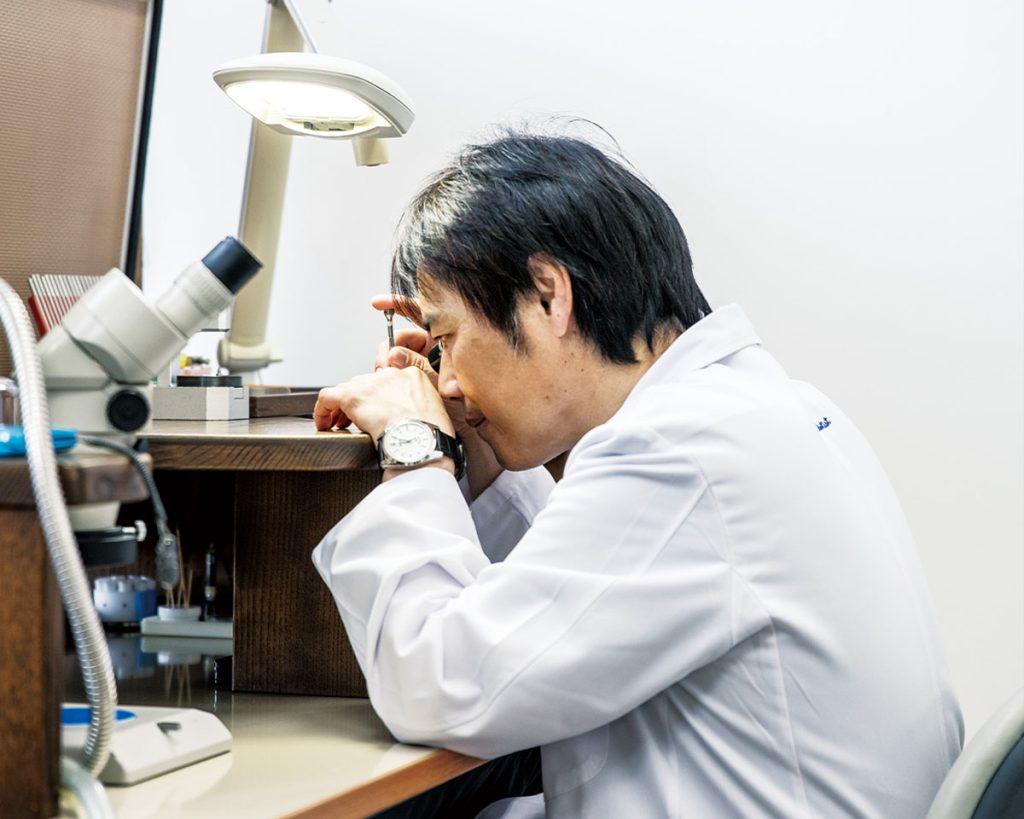

For luxury or high-end watches, much of the production is done by hand, whereas for entry-level or mid-range models, the process is largely automated.

This difference also applies to quality control. High-end watches are individually inspected by experienced personnel, while entry-level watches are inspected via automated processes.

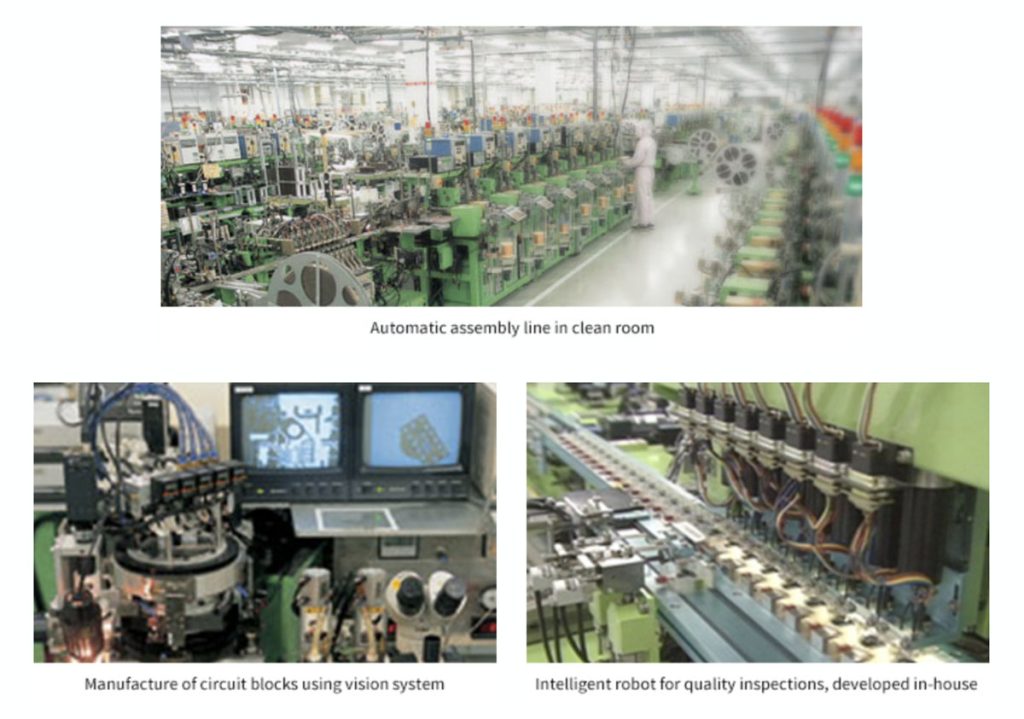

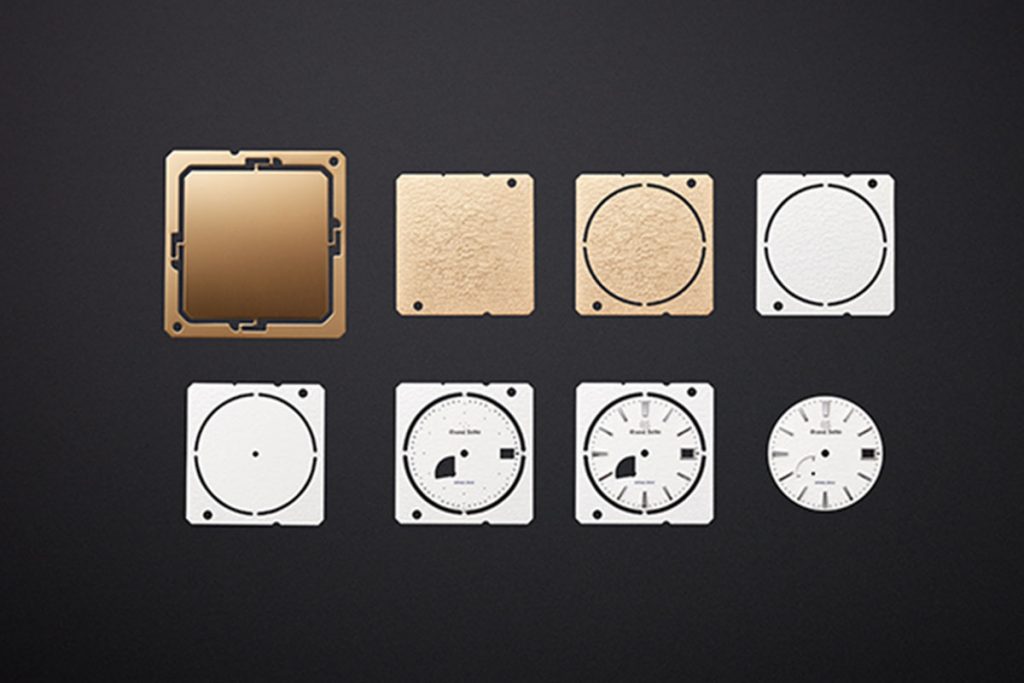

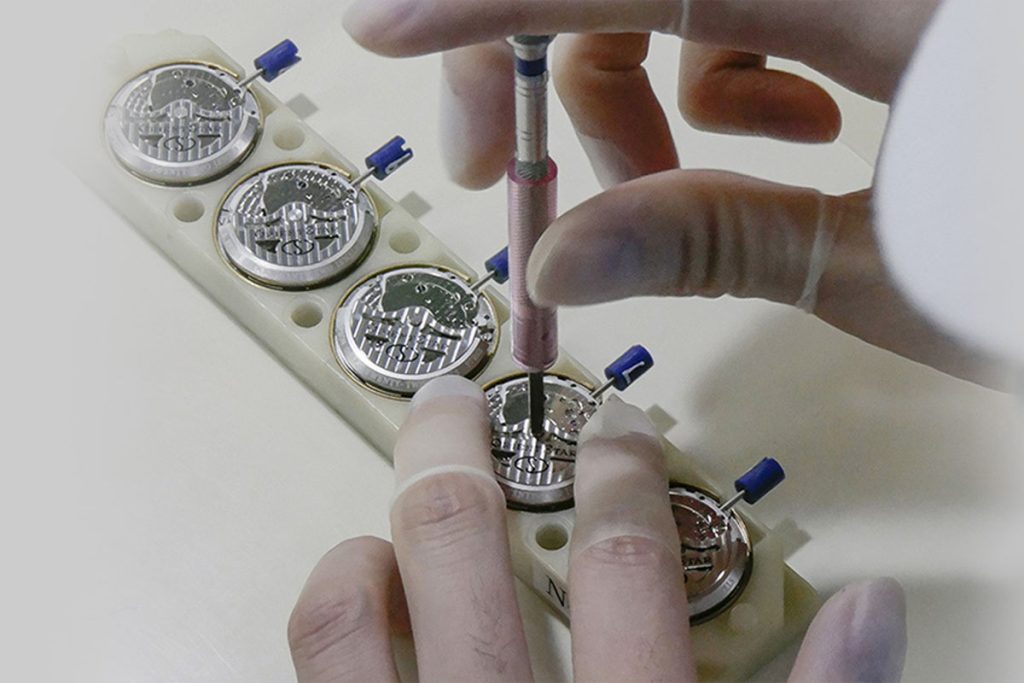

The following images, from the official Morioka Seiko Instruments website, illustrate the quality control process for high-end products (like Grand Seiko) versus mass-produced, lower-priced products, such as the analog quartz movements shown here.

These images of automated quality checks come from an area within Morioka Seiko Instruments in Shizukuishi that produces analog quartz movements. Here, the work is almost entirely carried out by robots capable of operating 24 hours a day, assembling the movement parts at a rate of one unit per second.

To wrap up this section on Morioka Seiko Instruments, here’s a list of some Seiko references that originate from Iwate Prefecture, according to official Seiko sources.

Once again, I must emphasize that, based on the “Made in Japan” rules we discussed earlier, some of these watches, especially in the lower price range, may also contain parts made in the group’s overseas facilities.

Examples of King Seiko produced at Morioka Seiko Instruments:

SJE089J1, SJE095J1, SJE103J1, SJE105J1, SJE107J1, SJE111J1, SJE113J1, SPB283J1, SPB285J1.

Examples of Prospex produced at Morioka Seiko Instruments:

SJE117J1, SJE119J1, SLA061J1, SLA077J1, SPB101J1, SPB103J1, SPB121J1, SPB143J1, SPB147J1, SPB249J1, SPB297J1, SPB301J1, SPB317J1, SPB323J1, SPB337J1, SPB375J1, SPB377J1, SPB381J1, SPB383J1, SPB451J1, SPB453J1, SPB455J1, SPB481J1, SPB483J1, SPB485J1, SPB487J1, SRQ051J1, SRQ053J1.

Examples of Presage produced at Morioka Seiko Instruments:

SPB091J1, SPB173J1, SPB205J1, SPB221J1, SPB225J1, SPB311J1, SPB331J1, SPB407J1, SPB415J1, SPB447J1, SPB449J1, SPB463J1, SPB465J1, SPB467J1, SPB469J1, SPB471J1, SPB478J1, SPB480J1, SRE015J1, SRPB41J1, SRPB46J1, SRPD37J1, SRPE41J1, SRPE43J1, SRPJ13J1, SRPJ17J1, SRPK93J1, SRPL07J1, SRPL09J1, SSA343J1, SSA397J1, SSA405J1, SSA439J1, SSA441J1, SSA459J1, SSA463J1, SSA464J1, SSK037J1, SSK039J1, SSK041J1.

Seiko Epson Shiojiri and the Shinshu Watch Studio

Nagano Prefecture, located in the heart of the Chubu region, is famous for its spectacular mountains and unspoiled landscapes. Dominated by the Japanese Alps, it offers breathtaking scenery in every season.

Not far from Lake Suwa, you’ll find the Seiko Epson factory in Shiojiri, where Spring Drive and a range of high-quality quartz watches are produced, among other things.

This is a large facility, subdivided into different areas, each dedicated to specific activities.

Here, you’ll find the famous Shinshu Watch Studio, which includes the Takumi Studio, where Grand Seiko and Credor watches with Spring Drive and quartz movements are assembled and inspected; the Case & Jewelry Studio, dedicated to case craftsmanship and gem-setting; the Dial Studio, responsible for dials; and the legendary Micro Artist Studio, where high-end timepieces in the Masterpiece line are made.

From the official Grand Seiko website:

The studio has the people, skills and technology to have mastery of every aspect of watchmaking from the development, design and production of movements to the manufacture, assembly and adjustment of complete watches, including cases, dials, hands and indexes. Thus the studio is one of the world’s few fully integrated “manufactures” and makes all Grand Seiko’s Spring Drive and quartz watches in-house.

Takumi Studio

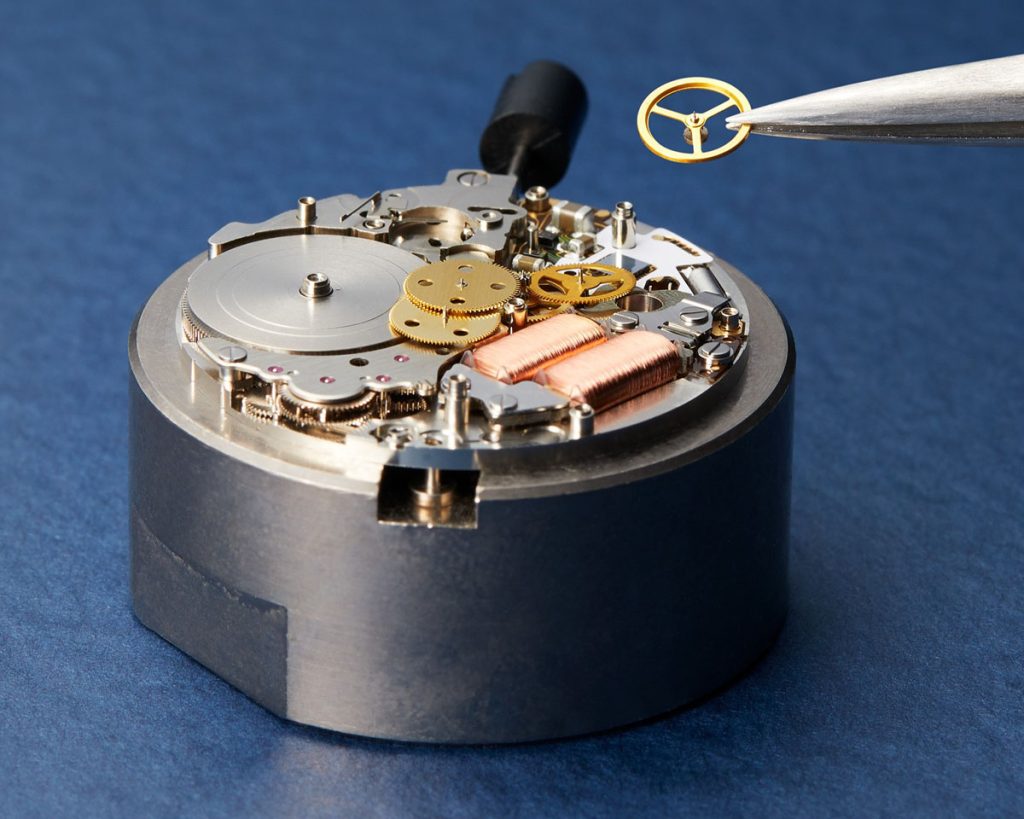

The Takumi Studio is responsible for assembling and quality-controlling Grand Seiko and Credor models equipped with Spring Drive and quartz movements. The work is done by hand by skilled watchmakers, ensuring high standards of quality and precision.

One among the many Spring Drive movements assembled by the Takumi Studio is the 9R86, comprising over 400 parts and fitted with 50 jewels. All these components are assembled entirely by hand, requiring great skill and experience.

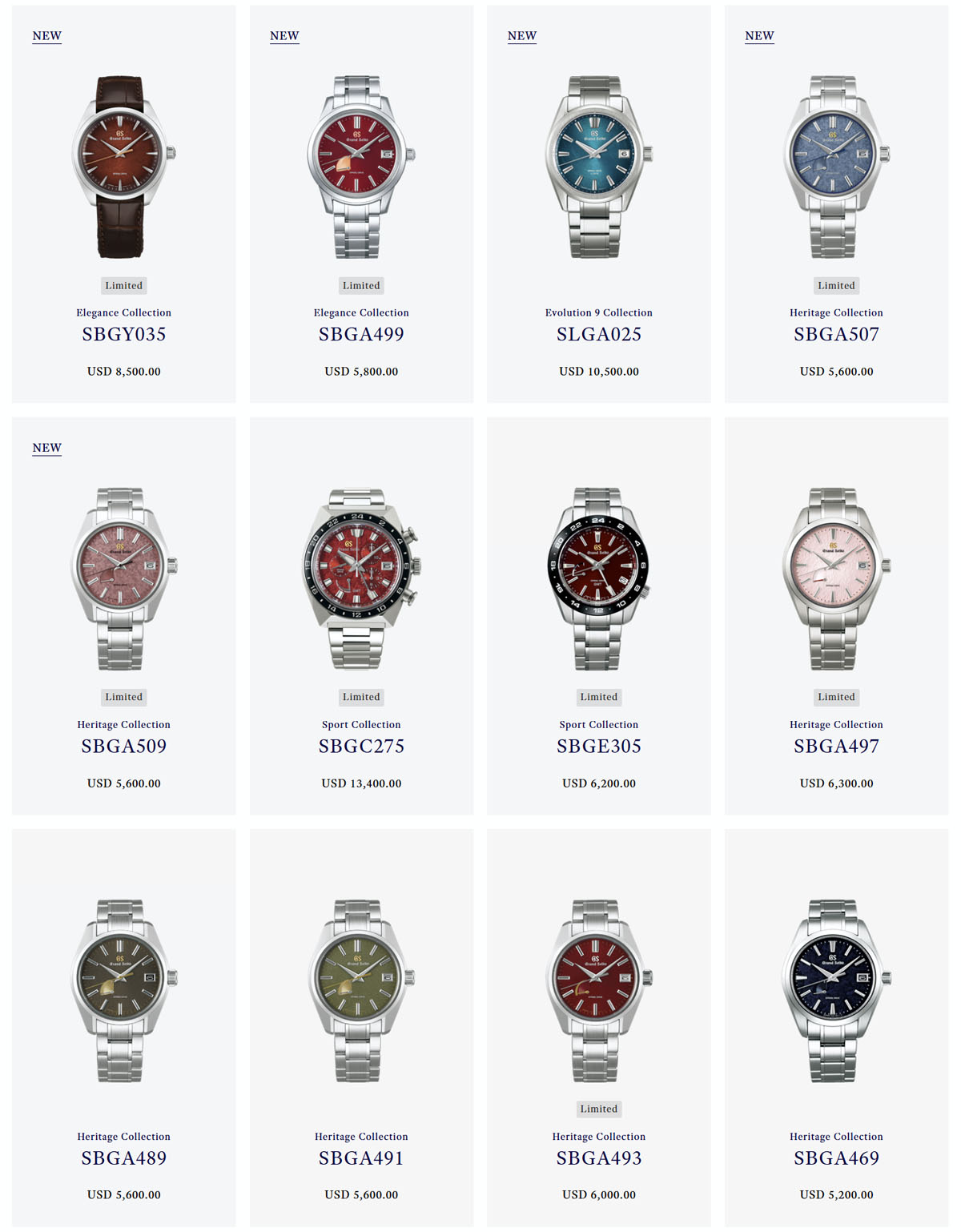

The following are some examples of Grand Seiko timepieces made in the Takumi Studio, which represent just a small fraction of the studio’s extensive collection.

Case & Jewelry Studio

The Case & Jewelry Studio handles every stage of producing luxury watch cases, from pressing to mechanical processing to final polishing. Skilled artisans here specialize in Zaratsu polishing, which is performed by hand on every case.

Beyond polishing, this studio focuses on brazing watch cases and bracelets made from precious metals, as well as manually setting diamonds and gemstones. The artisans use both traditional Japanese and Western engraving techniques to create watch-jewelry pieces with a unique identity, such as the Grand Seiko SBGD209 and SBGD207 shown below.

Collaboration among different specialized teams within the studio is crucial. For instance, the artisans in charge of polishing work closely with those who set the gemstones, ensuring that each element of the watch is harmoniously integrated. This synergy guarantees that every watch produced is not only functional but also a work of art.

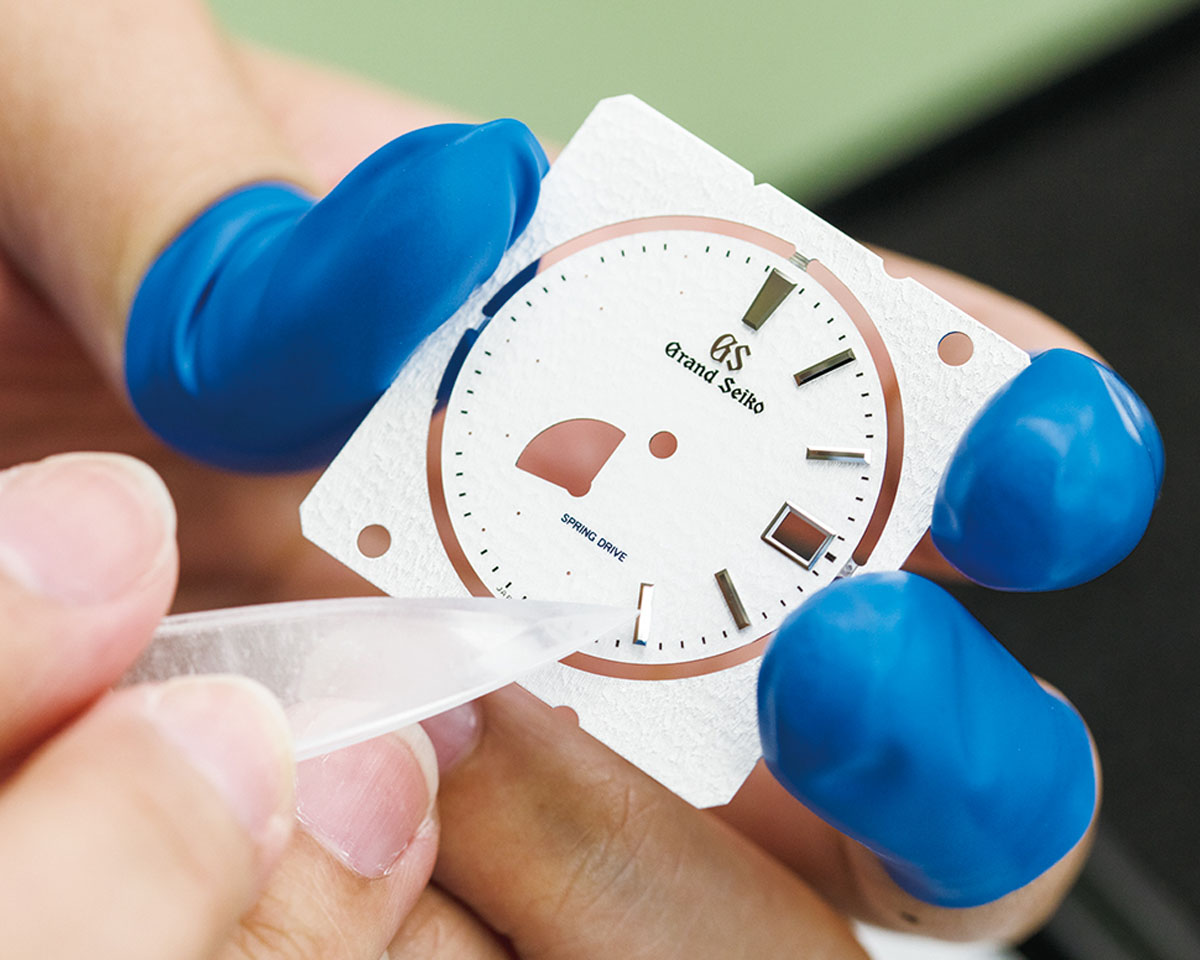

Dial Studio

This studio is renowned for its skilled craftsmanship and advanced techniques, creating dials of extraordinary beauty and precision. One of the most emblematic examples of the Dial Studio’s work is the famed “Snowflake” dial.

After cutting and drilling processes, artisans manually assemble each component, including markers and hands. Even their tools, such as tweezers and other instruments, are customized to ensure maximum precision during assembly.

Micro Artist Studio

Established in 2000, the Micro Artist Studio aims to preserve and pass down traditional Japanese watchmaking skills to future generations by crafting luxury timepieces that combine advanced technology with artisanal expertise.

From the official Grand Seiko website:

This studio was established in 2000 with the purpose of “uncovering, examining, and mastering the technologies and skills passed on by our predecessors for the production of luxury watches so that world-class Japanese watches could be created.” Today, the team consists of over 10 people, each one an expert in their respective fields including a skilled technician, Masatoshi Moteki, and a master watchmaker, Katsumi Nakata, who was selected by the Japanese government as a Contemporary Master Craftsman, a title given to technicians who possess outstanding skills and are leading experts in their fields. Nakata was also awarded the Medal with Yellow Ribbon, which is given, by the government, to individuals who have become public role models through their dedication to their work.

With “the idea and culture to cherish quality products” as its inspiration, the Micro Artist Studio’s goals are to produce “watches that last until their grandchildren’s generation” and to pursue “watchmaking that Japanese people could be proud of.” These ideals are displayed on the walls of the studio, serving as a constant reminder to the watchmakers of the studio’s guiding principles.

Among the Micro Artist Studio’s creations are masterpieces like the Grand Seiko SBGZ003, the Credor Minute Repeater GBLS998, and the Credor Eichi II GBLT997.

Each watch is assembled by a single master watchmaker, guaranteeing meticulous attention to detail and uncompromising quality.

Yoshifusa Nakazawa is a Japanese master watchmaker with decades of experience, responsible for assembling models like the Credor Spring Drive Sonnerie and Eichi II. He began his career in 1978 at Suwa Seikosha. In 1981, he won the gold medal in the “Watch Assembly and Repair” category at the World Skills Olympics in the United States.

Over the course of his career, he has received numerous honors, including the title of “Contemporary Master Craftsman” in 2008 and the Medal with Yellow Ribbon bestowed by the Emperor of Japan in 2015 for his contributions to watchmaking and for passing on his expertise to the next generation of artisans.

Seiko Epson Akita and the Akita Studio

In Akita Prefecture, also located in the Tōhoku region, you’ll find what used to be the main Japanese factory of the Orient group, today managed by Akita Epson Corporation, a subsidiary of Seiko Epson Corporation.

Among other things, this large facility produces both automatic and quartz watch movements.

Similarly to other Japanese Seiko group facilities, higher-end models (in this case Orient Star) are assembled by hand and individually inspected.

Hayashi Seiki Sukagawa, Koriyama, and Tamakawa

Hayashi Seiki Seizo Co., Ltd. is a company founded in 1921, specializing in watch case manufacturing and metalworking. Seiko Holdings owns a majority stake in this company, which has a very long history of working with the Seiko Group, even though it also manufactures watch cases for other brands.

The main headquarters of Hayashi Seiki Seizo in Japan is located in Sukagawa.

This is where watch cases for some Grand Seiko pieces and other group models are produced, as well as cases for other brands’ watches.

An example of watch cases manufactured at the Hayashi Seiki Sukagawa facility:

Besides Sukagawa, there are two other important Hayashi Seiki facilities in the region: one in Koriyama and another in Tamakawa.

The Koriyama facility primarily handles surface treatments, such as metal plating, while the Tamakawa facility focuses on producing various mechanical devices for a wide range of applications.

Other facilities in Japan

When we say Seiko makes virtually everything in-house, we really do mean everything, including synthetic quartz crystals. Two of the most important synthetic quartz production facilities are located in Aomori Prefecture in the north and Miyazaki Prefecture in the south of Japan.

Production of synthetic quartz crystals at the Aomori facility:

Seiko facilities worldwide

Between the late 1960s and early 1970s, Suwa and Daini Seikosha began expanding their production activities overseas, opening their first facilities in Singapore.

Singapore

In 1968, Tenryu (Singapore) Pte. Ltd. was established to produce watch cases, pressed components, and parts made using automatic lathes.

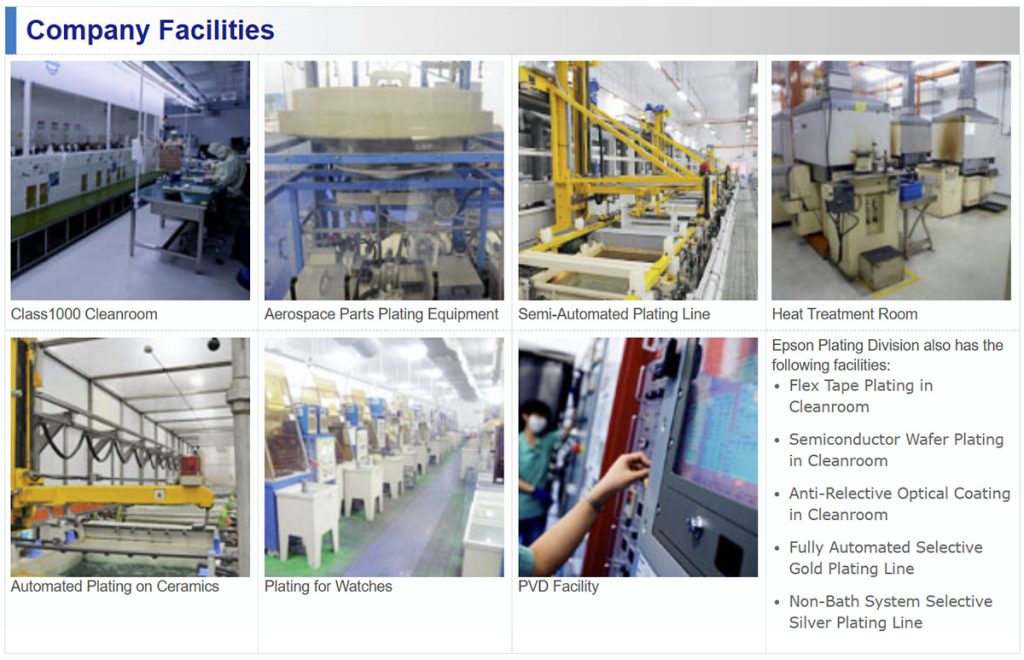

Today, Tenryu (Singapore) Pte. Ltd. is known as Singapore Epson Industrial Pte. Ltd. and primarily handles metal plating and other material treatments for a wide range of products, not just watches.

Following Suwa Seikosha (now Epson), in 1973 Daini Seikosha (now Seiko Instruments) founded the subsidiary Singapore Time Pte Ltd., which for a period managed the entire watch production process, from raw materials to final assembly.

In 1974, 89 employees were trained at Daini Seikosha in Japan to acquire the necessary skills for large-scale watch production.

Today, the company is called SEIKO Manufacturing (Singapore) Pte Ltd., and it no longer handles final watch production. Its main activities related to watches involve producing both mechanical and quartz movements.

Movement Manufacturing Division

Sub-assembly and assembly of mechanical and quartz watch movements. Supporting activities include Metal Machining (Turning, Milling, Drilling, Press, etc.), Surface Treatment (Heat Treatment, Polishing, Electro-plating, etc.), Flexible Printer Circuit, Micro-Electro Mechanical Systems, Journal Finishing, NC Milling, Injection Molding, Machine Maintenance, and the Design and Fabrication of Dies, Punches, Molds, Tools, and Jigs.

In 2019, Singapore’s digital platform OGS published an interesting report on this facility and how watch movements are produced. The video is available on YouTube at this link: https://www.youtube.com/watch?v=7Vwpt5zgC98.

Malaysia

The main production facilities for Seiko watches in Malaysia are located in Johor, at the southern tip of the Malay Peninsula, just north of the border with Singapore.

It’s no coincidence they’re located here: the company that manages them, Instruments Technology (Johor) Sdn Bhd, founded in 1990, is a subsidiary of Seiko Manufacturing (Singapore) Pte Ltd., which in turn is under the control of Seiko Instruments.

The Larkin plant was founded in 1990 for the production of movements and various watch components. Today, the facility’s operations include assembling and sub-assembling watch components and movements.

The Tebrau plant is more recent, established in 2001. Its activities include producing watch parts using automatic lathes, gear cutting, base plate/bridge machining, and metal pressing.

In the same area is the Epson Precision (Johor) Sdn. Bhd. factory, operating since 1988 under Seiko Epson. This facility has produced many products of various types, including watch cases, metal components, and even complete watches.

Another significant facility in Malaysia is Epson Precision Malaysia Sdn Bhd, located in the capital, Kuala Lumpur. Here, watches are not the main focus, but synthetic quartz crystals are produced.

Hong Kong

Seiko’s history in Hong Kong is very long, dating back to when it was still a British colony. As early as 1905, Kintaro Hattori opened sales offices there, and in 1968 Hattori (H.K.) Ltd. (today Seiko Hong Kong Ltd.) was established.

Production activities began with the founding of Suwa Overseas Ltd. in 1974, later becoming Epson Precision (Hong Kong) Ltd. In 1987, Seiko Instruments (H.K.) Ltd. was also launched, with both companies involved in assembling and producing various watch components.

Over the years, much of the production seems to have shifted from Hong Kong to mainland China, but at least some operations still appear to be carried out in Hong Kong.

In particular, looking at official Seiko data, Hong Kong is listed as the origin of many “K” models in the new Seiko 5 Sports line, as well as other entry-level series.

Examples of watches produced by Seiko Manufacturing (H.K.) Ltd.:

SRPD51K1, SRPD53K1, SRPD57K1, SRPD59K1, SRPD61K1, SRPD63K1, SRPD65K1, SRPD76K1, SRPE53K1, SRPL11K1, SRPL13K1, SRPL29K1.

Mainland China

Seiko’s production activities in mainland China seem to have begun between the late 1980s and early 1990s with the opening of the Dalian Seiko Instruments Inc. facility, expanding steadily over the years.

Established in 1989, Dalian Seiko Instruments Inc. operates as a subsidiary of Seiko Instruments. Among its various operations is the production of watch components.

Today, another significant production hub in mainland China seems to be in the Guangzhou area, home to Guangzhou SII Watch Co., Ltd., controlled by Seiko Instruments.

Examples of watches produced by Guangzhou SII Watch Co., Ltd.:

SFJ001P1, SFJ005P1, SFJ007P1, SNE595P1, SNE597P1, SNE599P1, SRE004K1, SRK048P1, SRPH92K1, SRPF79K1, SRPF81K1, SRPG18K1, SRPG27K1, SRPG29K1, SRPJ93K1, SRPK09K1, SRPK11K1, SRPK29K1, SRPK33K1, SRPK35K1, SRPK43K1, SRPK65K1, SRPK67K1, SRPK87K1, SRPK89K1, SRPK91K1, SRPK97K1, SRPK99K1, SRPL31K1, SRPL35K1, SSB407P1, SSK001K1, SSK003K1, SSK005K1, SSK023K1, SSK033K1, SSK035K1, SSK036K1, SUR507P1, SUR517P1, SUR523P1, SUR525P1, SUR527P1.

Thailand

In 1988, Seiko Instruments opened a facility in Thailand focusing on the production of various watch components. Today, it primarily produces electronics and IT-related products, while most of the watch-related production has been relocated.

There are also facilities of Epson Precision (Thailand) Ltd., under Seiko Epson, producing a wide variety of goods.

Despite Seiko’s presence in Thailand, watches represent only a small portion of its local production.

What are the differences between Seiko J and K?

In Seiko’s catalogs, letters such as J and K often appear at the end of a reference, sometimes followed by a number, indicating different versions of the same model.

Given that Seiko uses these codes internally and has never publicly clarified their meaning, we can observe that “J” models are “Made in Japan”, while “K” models are not.

The same reasoning applies to “Made in Japan”, meaning it doesn’t guarantee that every single component of the watch was made in Japan, but rather that the watch underwent a “substantial transformation” in Japan.

Although we don’t know what “K” actually stands for, I hypothesize there might be a link to the Japanese term “Kaigai”.

In Japanese, the common term for “abroad” is 海外 (Kaigai). Specifically referring to items made abroad, the expression 海外製 (Kaigai-sei) is used, meaning “produced overseas”. I stress that this is my speculation, with no confirmation or denial from Seiko.

As for potential quality differences, keep in mind that Seiko manufactures nearly everything in-house, and despite having facilities all around the world, standards are directly controlled by Seiko. This ensures consistent quality, regardless of the country or facility of origin.